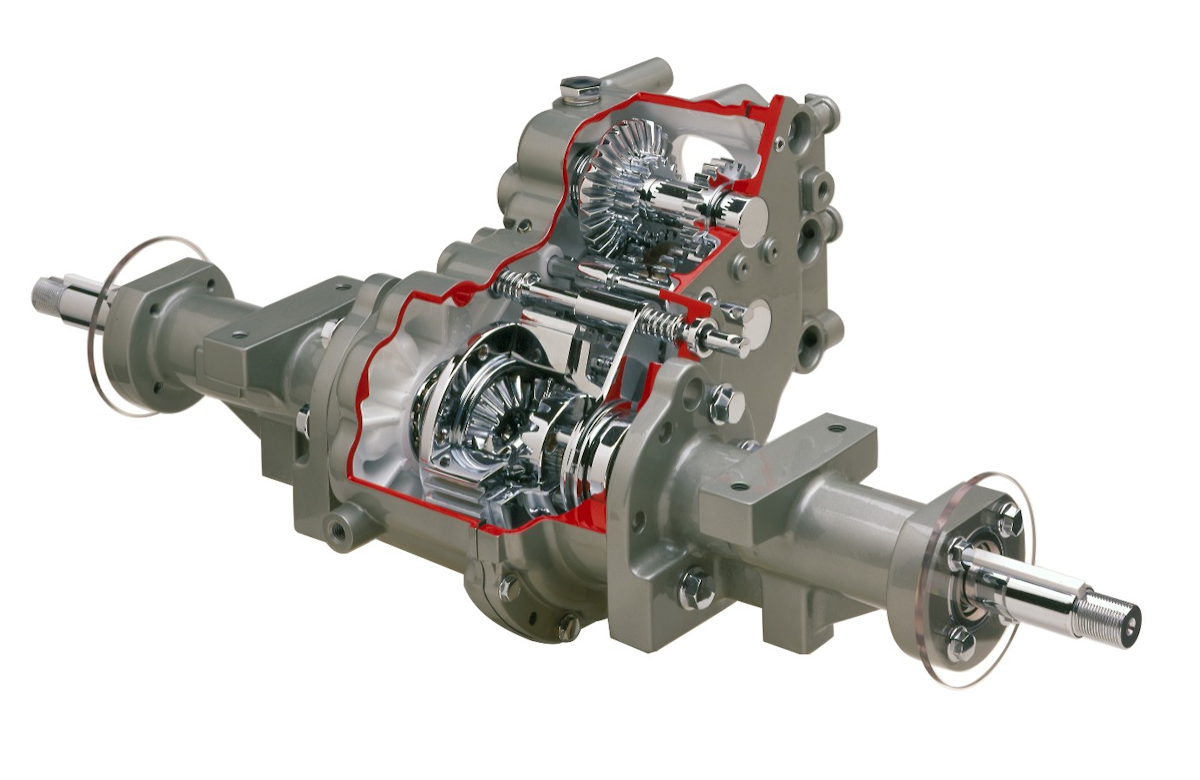

The Mendeola S4 transaxle was designed to address some limitations of the MD series. The S4 started from a clean sheet of paper, designed to be the next level in strength and performance. The S4 uses industry proven Weddle Racing 10' ring and pinions coupled to a new line of Weddle Racing gears made specifically or the S4 transaxle.

- We stand behind every transaxle we build because we build them all ourselves. The guy you talk to on the phone, is the same guy who builds and then ships it. Nothing goes out our door without our fingerprints all over it literally.

- TRANSAXLE LLC / ASHOP. Math question 7 + 3 = Solve this simple math problem and enter the result. For 1+3, enter 4. To learn more about TransAxle LLC visit our company's website.

Transaxle from a C5 Corvette. (Image/Corvette Central)

Quickly, what does a Porsche 911 and a 1961 Pontiac Tempest have in common?

If you said “they both have a transaxle,” then you probably read the headline of this article. Garageband for mac os x lion 10.7 5 download.

In most cases, a transaxle is a single unit that houses both the transmission and the axle assembly—simple to describe, but mechanically complex.

Think about it: A transaxle combines the function of the transmission and axle, along with other potential variables like a limited-slip differential and independent suspension.

Why do Vehicles Use Transaxles?

The prevalence of the transaxle design grew with the increase of front-wheel drive (FWD) cars. The setup eliminated the need for a driveshaft, and allowed the drive wheels to connect directly to the transmission. Its relatively compact design lent itself well to a small engine bay.

But transaxles have been around for a long time—and they aren’t unique to only front-engine, front-wheel drive vehicles either.

One of the most popular cars in history, the original Volkswagen Beetle, required a transaxle, thanks to its rear-engine, rear-wheel drive layout.

In fact, transaxles can be found in vehicles stretching back to the early days of the horseless carriage. Sketchup free download 2017 for mac.

Porsche’s 928, developed in the 1970s, shares the same aft-mounted transmission/transaxle setup found in 1997+ Corvettes. (Image/Jalopnik)

Is There a Performance Benefit to a Transaxle Configuration?

Several high performance cars have incorporated a transaxle setup (and we’re not just talking about rear-engined Porsches).

On a front-engined, rear-wheel drive car, the transmission can be moved to the rear and turned into a transmission/axle combo. In this type of configuration, the transaxle is linked to the engine via rigid torque tube.

…

A torque tube is not a driveshaft. Though they provide a similar purpose, a driveshaft is allowed to flex and adapt to angle changes between the transmission yoke and the rear axle pinion yoke. A torque tube is typically a rigid cylinder that’s bolted directly between the transmission and the engine. A spinning steel shaft inside the tube connects the engine crankshaft/flywheel to the input shaft of the transmission. Since the torque tube design doesn’t handle the amplified torque output from the transmission, the propeller shaft inside the torque tube can be far less robust than a driveshaft.

…

Locating the transmission rearward allows engineers to achieve better front/rear weight balance, ultimately resulting in better handling.

Corvettes have used rear-mounted transaxles since the introduction of the C5 generation in 1997. Back in the mid-1970s, Porsche used a transaxle in the front-engine 924, and again in the 944 and 928.

Even Mercedes’ iconic gullwing SLS AMG has a rear-mounted transaxle.

…And the Tempest had One Too?

Yep.

General Motors went a little wacky in the 1960s when it gave the go-ahead to two unorthodox (for GM, at least) transaxle cars—the Corvair and the Tempest.

Unlike the Corvair’s rear-engine setup however, the Tempest kept the engine up front, and used the aforementioned torque tube to deliver power to the rear-mounted transaxle.

Among other innovations, the Pontiac Tempest’s clever “Rope Drive” featured a curved steel shaft inside the torque tube that was tuned to absorb the vibrations from the engine—and it worked. Unfortunately, we didn’t get to see the technology evolve, as the Tempest went to a conventional setup in 1964 with the engine and transmission in front, and the axle out back.

The 1961 Pontiac Tempest used an innovative “Rope Drive” that linked the engine to the rear transaxle. (Image/The Truth About Cars)

Can I Take My Transaxle Racing?

Sure. Local autocross courses are full of transaxle cars, be they front-wheel drive, Corvettes, or the occasional Porsche 924. Many sport-oriented FWD cars through history offered limited-slip differentials from the factory, including the Honda Civic Type R, Nissan SE-R, and Volkswagen GTI.

In fact, companies like GForce Engineering Epson printer l382 driver download for mac. sell half-shaft upgrades for high-performance cars with transaxles—like the 1997+ Corvette.

Nissan’s Sentra SE-R was a FWD factory hot rod that came with limited slip differential inside its transaxle. (Image/Road & Track)

Transaxle Care

Whether your transaxle vehicle is a daily driver or a weekend track toy, the key to both transaxle reliability and performance is regular maintenance. Check for fluid leaks. Replace gaskets and seals as necessary.

A typical fail point on a transaxle is the axle shafts themselves, typically at the CV joint. They’re usually covered by a plastic or rubber boot to prevent water and muck from entering the joint. Those boots should be inspected regularly.

Properly serviced, a transaxle is every bit as reliable as a traditional standalone transmission-and-axle setup.

Because the overwhelming majority of mid-engine cars use the Graziano transaxle as used in Audi and Lamborghini cars, and available from RCR/Superlite, this manual will focus on that unit. However, there is a wide range of transaxles that could be used, from Audi to Xtrac. For more details on other transaxles, their benefits and drawbacks, and installation details, check out the transaxle page on the SL-C wiki.

Tools and materials needed

- Transaxle Completion kit, and/or separately-sourced clutch, hardware, dowels, engine-to-transaxle adapter plate, etc.

- Small tapping hammer with a soft head, 180-grit sandpaper, wrenches, sockets, allen wrenches as needed.

- For LS engines: Grinder or Dremel tool able to remove aluminum from LS oil pan.

Estimated time

About 6-8 hours, taking your time, including modifying the oil pan on an LS engine.

Adapter plate installation

If you ordered your kit with a Superlite-manufactured adapter plate for the Graziano and a GM LS-series engine, the first step is to bolt the adapter to the transaxle, as shown in the following pictures.

The preferred method is to start by using two alignment dowels to mount the plate to the transaxle. These can be ordered from any Audi dealer, and are part number 086-351-153-A. You need to order two, and they are around $7 each.

The dowels press-fit into the adapter plate. Use a small tapping hammer if necessary, but be sure they are tapped in straight, and that the edges are not damaged in the process. Take your time, and sand the outside of the dowel if needed.

The transaxle can be aligned without these dowels, but mis-alignment is much more likely without them, so they are cheap insurance. A mis-aligned engine-transmission unit can be very expensive, so don't skimp here.

The picture below shows the lower left alignment dowel inserted in the adapter plate, with a bolt through it.

Note the positions of the dowels in the plate below, and the amount they stick out from the plate. This is important for accurate fit-up.

The picture below shows an adapter with all the bolts and dowels inserted, ready for it to be attached to the engine.

Transaxle Manufacturing Of America

Once the dowels and bolts are in the plate, attach it to the transaxle. When the plate is bolted to the transaxle, it is ready to accept the engine (with clutch and flywheel attached). Use the Allen-head bolts provided in the Transaxle Completion Kit to attach the plate to the transaxle. Torque them to ??? ft lbs.

Attaching the flywheel

Bolt the Superlite-provided custom flywheel to the crankshaft of the engine using the hardware provided in the Transaxle Completion Kit, and torque to ??? ft lbs.

Attaching the input bearing and clutch

The Graziano-specific pilot bearing or input bearing can now be installed into the flywheel. This is part of the Transaxle completion Kit, or can be sourced from reputable bearing suppliers. It has an OD of 43 mm and an ID of 15 mm.

Note that unlike many domestic engines, this bearing must be installed in the flywheel, not in the crankshaft. You can carefully tap it into place with a soft hammer, or use a press if you have one with a big enough throat. When installed correctly, the bearing lip should be flush in the hole in the center of the flywheel.

Once the bearing is in the flywheel, bolt the clutch to the flywheel with the hardware provided in the Transaxle Completion Kit. Be sure to align the clutch with the flywheel. Most builders use a clutch alignment tool like this one, as it is cheap insurance against a mis-aligned clutch and flywheel.

Carefully torque them to ??? ft lbs, gradually working up to the final torque, rotating the torque wrench in a circular pattern.

The clutch is a stock Audi or Lamborghini unit capable of holding high power, but stronger clutches are available- see the wiki for details.

Attaching the ring gear

Once the clutch is attached to the flywheel, install the ring gear that is part of the Transaxle Completion Kit (or order the appropriate ring gear from local Audi dealer or online).

There is an indent in the pressure plate and ring gear- use this to align them, bolting them together using the hardware from the Transaxle Completion Kit.

Torque the ring gear to the flywheel to ??? ft lbs.

Joining the engine and transaxle

It’s a good idea to join the engine and transaxle as a unit outside of the car, as it makes it easier to both attach the two assemblies, and also to install them as a unit into the car.

Before you join the engine and transaxle, make sure you have clearance between the engine and transaxle. Because the Graziano originally came out of cars with all-wheel-drive, there is a front-facing output shaft. This commonly interferes with some engines. In order to maintain the transaxle warranty, do not cut off the end of the output shaft. Instead, using a small grinder or Dremel, grind off the area of the block (on an LS engine) or oil pan (on a Ford mod motor) as needed. If you are using a different engine, check it for clearance, and make adjustments as needed.

Here’s a picture of a Ford mod motor showing the modification:

Below is a picture of an LS engine with the required modifications to the block:

Once you have the clearance made in the engine as needed, you are ready to bolt the engine (with flywheel and clutch) to the transaxle. To begin, push the transaxle and engine together, making sure that the two are perfectly aligned. If the clutch was installed correctly using the alignment tool, it should slip on the input shaft of the transaxle.

If there is any resistance, don't force it. Resist the urge to 'pull them together' using the bolts. Expensive damage will almost certainly result. It may take a few tries, to get the alignment perfect, but when you do, the two parts will join up correctly.

Once joined, the fasteners provided in the Transaxle Completion Kit can be used to tighten up the assembly. Torque the engine-to-adapter bolts to ??? ft lbs.

Starter

The starter can be installed now, with the provided fasteners in the Transaxle Completion Kit. It's easy- just insert it into the starter pocket on the transaxle, and bolt it up.

Torque the starter bolts to no more than ??? ft lbs.

Axles

Your kit likely came with axles with CV joints already installed. You can install them now with the hardware that came with the axles. Clean the threads of the fasteners of all grease, clean out the holes in the transaxle bells to which the axles bolt, use Blue Loctite on the last 1/2' of the thread ends,and torque to 58 ft lbs, per The Driveshaft Shop.

Reverse light wiring

The Graziano transaxle is equipped with a reverse switch. The connector is easy to find, and is VW part number 1J0 973 702. A pigtail with this connector can be found from the usual sources, including eBay.

InfinityBox Harness:

The Infinitybox harness doesn't have a provision for a reverse light, but one is easy to implement. Select an unused output wire from the rear Mastercell, and wire it through the reverse switch to the backup light(s) you select. If you are using the standard tail lights, just insert a bulb in the inner light opening, and wire the two lights in parallel, You'll need to re-program the powercell output to come on when you want it to (probably when ignition is on), unless the output is already on when you need it powered. Reprogramming Infinitybox powercells is easy, and can be done at your home with an inexpensive programmer from Infinitybox, or by Infinitybox themselves. In any case, you'll need an updated program from Infinitybox, so contact them for more details.

All other harnesses:

Transaxle Control Module

The chassis harness has a circuit for the reverse light. There is a connector for the transaxle, and a circuit for the light. Since there are too many possible reverse light scenarios, you will need to connect the wire to the reverse lights you implement.

Starter wiring

The transaxle uses standard VW-family connectors for the starter control circuit. For the main power, use a large ring connector and at least #4 wire.

Transaxle Cinnaminson Nj

For the starter control, use the following parts:

1.Connector 357972771

2.Wire repair kit 979227E

Sequential Transaxle For Street Use

3.Wire seal 1J0972743

Using the parts above, terminate the wire from the chassis harness so it plugs into the starter.

Racing Transaxle For Sale

These parts should be available from any VW dealer. Thanks to Dan C for this info!